Investigate aspects of mining in south africa

The mining industry is one of the most important contributors to the economy in South Africa. In this chapter, you will learn about the history of mining in South Africa, as well as the impact that mining has on communities, social life and the environment.

Four topics about mining are discussed in this chapter. You will work in teams, and each team will investigate only one of these topics, then give an oral report to the class on your topic. You will work in teams of three or four, and there must be at least one boy and one girl in each team.

Notes to the teacher

Learners will present their research on different topics as teams in the last 60 minutes of the week. Ensure that teams are an appropriate size so that there will be at least four minutes for each team to present their research. This means that there cannot be more than 15 teams (15 × 4 minutes = 60 minutes).

Different teams will present research on different topics. There are four different topics. Assign a topic to each team, rather than letting learners choose for themselves. Letting them choose would mean that learners will take time to make their choices (there is no time to waste time during this week's work), and might result in certain topics being left out or not presented properly.

5.1 Background information on different mining topics (30 minutes)

Learners should read and make summarising and comprehension notes on the topic they were assigned. This is individual work. Thirty minutes is not enough time to do this, which is why learners were given homework at the end of the previous chapter to read the articles on their assigned topic. Important: This means that you will have to assign topics to teams at the end of the previous week.

If you have access to the internet and/or books and/or video material, you should use this to make more information available to learners on the different topics. For example, you may make a list of appropriate websites to consult, or may make photocopies for learners of newspaper articles that have to do with the topics.

5.2 Team discussions and preparation of reports (30 minutes)

Learners should work together in their teams to prepare their reports. Comprehesion questions are given to guide them through their topics.

For homework, learners also have to read the articles on the other topics. This is crucial as teams will be required to ask questions of other teams after each presentation. Reading the articles on all the topics will ensure that the teams can ask informative questions.

5.3 Presentation of reports

Ensure that the teams adhere to the time limit for each presentation. Also allow time for the class to ask questions of each presenting team, which the team should answer.

Background information on different mining topics

Your teacher will divide your class into different teams, and tell each team which topic they need to investigate during this week. Each team will only investigate one of the following topics:

- The impact of mining on the environment: Acid mine drainage

- The impact of mining on the environment: Dust pollution

- Indigenous mining in South Africa before the modern era

- The equality or inequality of job opportunities in mining for men and women

In this lesson, you will work individually and read an article about the topic that your team will investigate. After reading the article, you should make notes in the space provided. Write down the points that you think are most important, as well as the points on which you would like to get more information. For homework, you should find out more about these topics, for example by looking in books, asking older people and looking on the internet.

The four different articles are given below. Remember that you should only read the one article that is about the topic your team will investigate.

Topic a: the impact of mining on the environment: acid mine drainage

Mining is very important to South Africa. The mining industry has led to our country becoming very important as a provider of metals and ores. South Africa is one of the biggest producers of precious metals such as gold and platinum, and the country also has large amounts of iron, zinc, chrome and copper ore that are very important to many of our factories. Coal is also mined and this mineral provides the energy for many of our power stations.

An ore is a type of rock that contains important minerals, including metals. These ores are mined and then refined to extract the valuable material.

Because mining is such a large industry, it also provides employment for large numbers of people, both skilled and unskilled.

But, like any industry, it is also a cause of problems due to the way the ore is being mined. Before you investigate these problems, you need to understand a little about the mines themselves. Some mines are known as opencast or surface mines. These are mines where the workers do not have to go underground, but instead dig a very large hole to remove the ore after stripping off the surface material. These mines are easier to work on. Coal mines and iron-ore mines are often opencast mines, as coal and iron ore are closer to the surface than precious metal ores, such as gold.

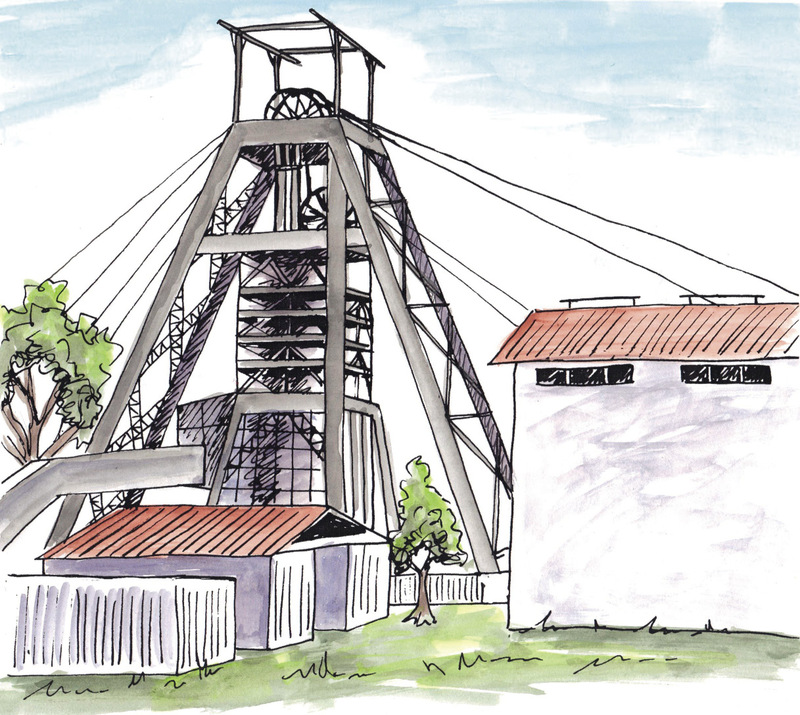

Underground mines are mines where shafts and tunnels have to be dug to reach the supply of ore that is being mined. All of South Africa's gold mines are underground mines, with shafts that are sometimes kilometres deep. The deepest mine in the world is the TauTona mine in Carletonville, South Africa: it is nearly four kilometres deep! Mining is dangerous work, and there are very strict safety precautions on all mines.

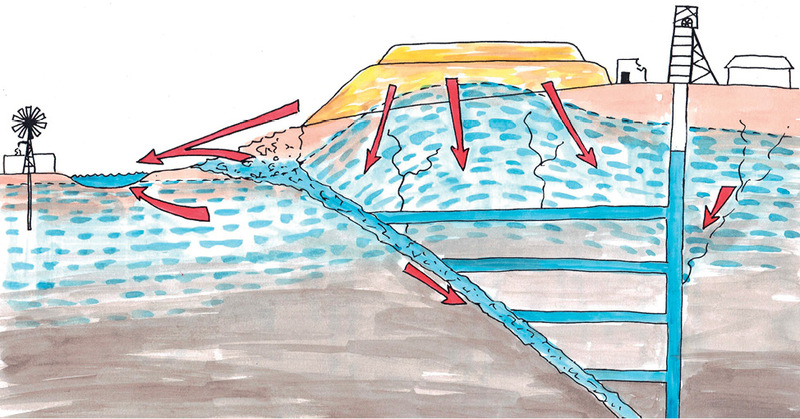

One of the problems with mining is that eventually the ore, or metal, will run out. When this happens to a very big mine, what is left are many kilometres of underground tunnels. It is impossible to fill these tunnels because the ore that was mined has been processed to remove the valuable mineral. What happens normally is that the mine entrance is sealed and the tunnels are left as they were during mining. But they don't stay empty.

If you have ever dug a hole in the ground near a river, or on a beach, you will know that water soon starts gathering at the bottom. This happens when you have dug beyond the water table.

The water table is the level in the ground where enough water is present to flow.

All mines that are underground will be dug beyond the water table. While miners are working underground, large pumps are constantly pumping the water that gathers in the tunnels out of the mine. But once the mine is abandoned, the pumps are removed and the water starts to build up, exactly as it would in the hole you dug.

It would be fine if this water just filled the mine, but a chemical reaction occurs as the water drains through the rocks into the mine. The water reacts with chemicals in the ground that contained the ore, and turns into an acid. Acids can be very destructive in the wrong environment.

A chemical reaction takes place when materials react with other chemicals and a change occurs to the molecules of the materials, forming new substances.

You come across mild acids every day. Try this experiment:

At home, pour yourself a glass of water, and then add one teaspoon of vinegar and stir. Take a sip. It is healthy, but for most people it tastes too strong, as if it is burning your mouth and throat.

Now pour yourself another glass of water. This time, add three teaspoons of vinegar to it and stir. Now drink a little bit from this glass as well. Could you taste the difference? Scientists would say that the first glass of water was slightly acidic, and that the second glass of water was more acidic.

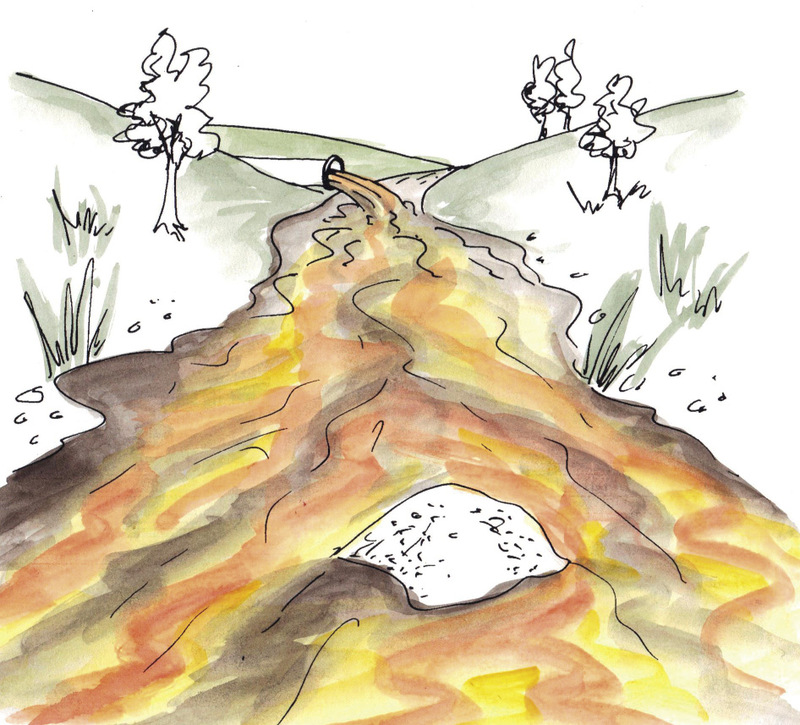

The acid that is produced in mines is a lot stronger than your vinegar water! The water has mixed with sulphides and can eat away solid metals and stone. It is very poisonous to plants and animals.

Acidic liquids are very corrosive. They can destroy solid materials.

It would be less harmful if the acid water stayed in the mine, but due to many reasons the acidic liquid often leaks out. In some cases, the water level in the mine rises to the level of the surrounding water table, and then the acid pollutes all the water in that area. In other cases, the surface of the mine is higher than surrounding areas. Remember that most of the gold mines in Johannesburg were on a ridge. The acidic liquid will flow out of gaps in the rock like an ordinary spring, and pollute the rivers and streams it enters, killing fish, animals and plants.

When large mines, such as the gold mines in Gauteng, are closed, acid leaking from the mines can cause a lot of problems to the surrounding environment. These problems have to be solved before communities have to be removed to escape the effects.

The gold mines in Gauteng are located on the Witwatersrand, or the "White Water Ridge". Rivers flow away from each side of this ridge, and are easily polluted.

Notes: Acid mine drainage

Topic b: the impact of mining on the environment: dust pollution

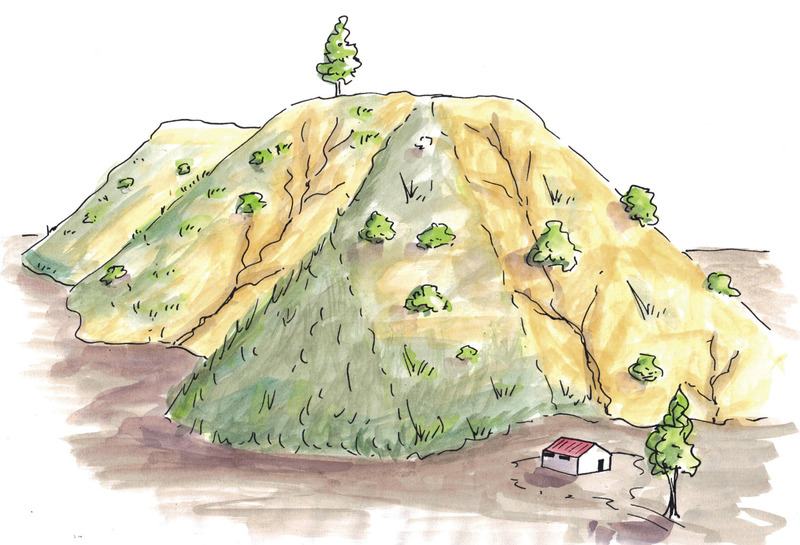

Anyone who has been to Johannesburg will know the mountains of yellow and white sand that comes from the mines. These are called mine dumps. What are these dumps actually made of, and why do they exist?

Ore has to be crushed and then treated with chemicals before the metal in it can be dissolved. After this the chemical that contains the dissolved metal is separated from the waste material, then more chemicals are added and the metal is recovered. The metal is then melted and poured into large ingots, or bricks, of metal that can be transported to the factories that will use them.

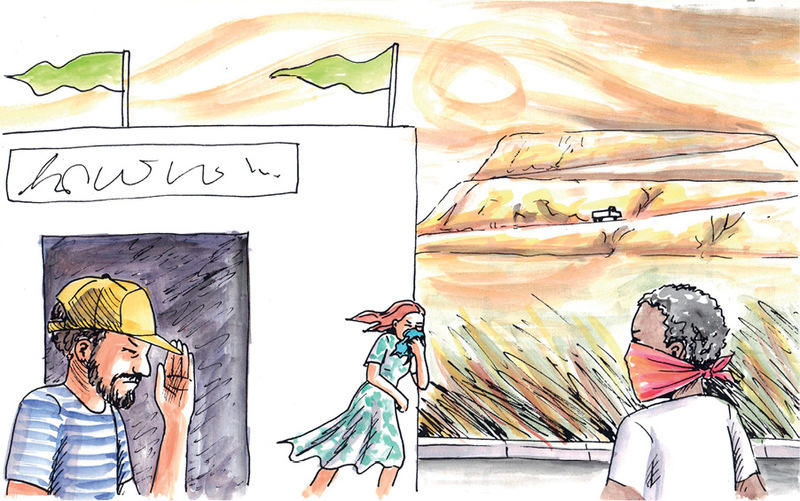

But what remains? All the crushed ore and chemicals that have been used to extract the metal become waste material that has to be stored. It can't be put back into the mine since people are still working there, so it is either put into large dams, or piled in dumps. The waste material is normally a mixture of water, dissolved chemicals, and finely ground dust or small particles. This is called "slurry". The slurry has to dry in the open air. A ton of gold ore only produces a gram or two of gold, so a lot of slurry is left after extracting the gold.

Many of the chemicals added to extract gold are still in the slurry, and some of them are very poisonous, such as cyanide.

The compounds in the slurry are ground to fine sand. Once the water dries, it leaves a layer of tiny particles that can easily be blown around.

When gold mines in Johannesburg first started producing waste material, the slurry was pumped into storage dams. After a while, as the slurry dried and more waste material was produced, the dams grew upwards into dumps. The centre of these dumps was lower than the outside, so that more slurry could be pumped into the middle. The slurry was then pushed out towards the edges as it dried, leaving more space in the middle. These dumps grew into the huge mine dumps that line the mining areas of Johannesburg.

It is not just gold that produces mine dumps. However, since the old gold mine dumps in Johannesburg are so close to communities living there, it is a very noticeable problem. Other mining towns and cities have similar problems. When new mines start, people working at the mines often build houses nearby, and often a whole town develops around a mine.

In the early days of mining, the impact of mine dumps on the environment was not known. Once people became aware of the negative effects of the dust that comes off these mine dumps, they started looking for a solution to this problem. First, trees and grass were planted on the mine dumps to prevent the wind from blowing the dry dust into the towns.

But because of the toxic chemicals in the dumps, the trees and grass did not grow very well. Later, mining companies started to extract any remaining gold from the waste material in these mine dumps. Since the process used to extract gold a hundred years ago was not very effective, a lot of gold remained in the waste material. Once they processed these mine dumps to extract any remaining gold, they removed the dumps altogether. The remaining waste material was then stored where it could not be blown into nearby towns or cities.

Notes: Dust pollution from mine dumps

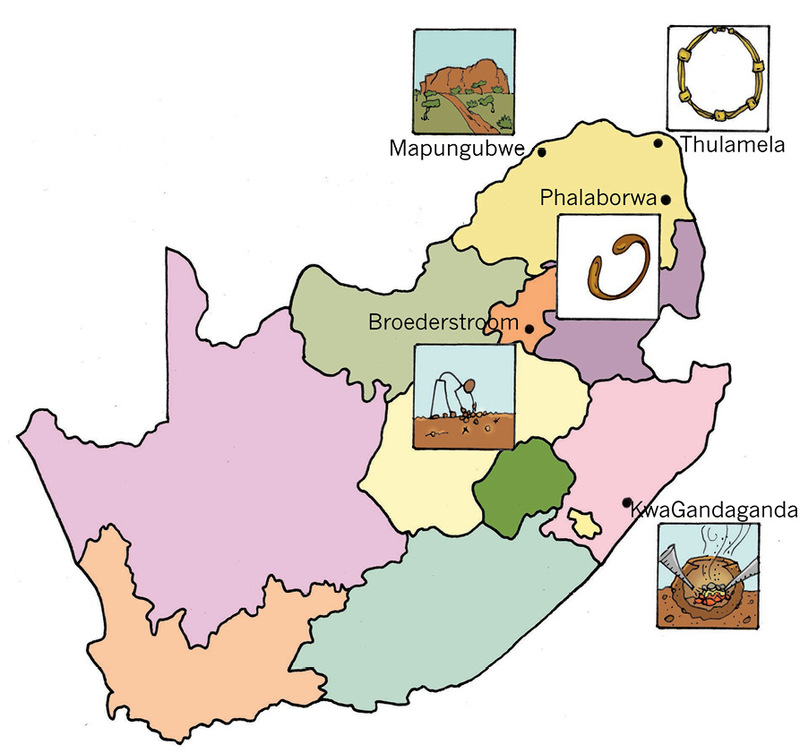

Topic c: indigenous mining in south africa before the modern era

The history of South Africa is closely linked to mining. Gold and diamond mining has generated much wealth for the country over the last 150 years. The mines in South Africa today produce gold, diamonds, silver, platinum, chromium and many other minerals. In 2010, South Africa produced 15% of the world's gold, and 78% of the world's platinum supply.

But of equal importance to our history was the ability to make iron tools and implements. This period is known as the Iron Age. The ability to smelt ore and make iron tools was discovered in North Africa. Some of these communities moved southwards to find better rainfall and more productive land to provide crops.

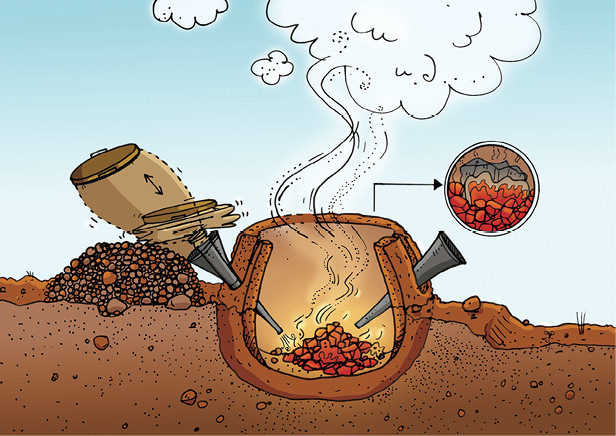

Smelting is the process where ore is melted in a very hot oven called a "furnace", to separate the iron from the rest of the ore.

About 1800 years ago, the areas where people coming from the north would settle in was influenced by the discovery of iron-ore deposits. Even nomads would settle near a source of iron ore and plant crops such as ground beans, sorghum and millet.

Nomads are people who have no fixed homes, and move from place to place in search of water and food.

This would lead to an increase in cattle and other stock animals, and often the community would grow and prosper in that area. They would stop their nomadic lifestyle and stay in one place to build a community. However, sometimes they would have to move to a different area due to drought or poor soil. Other groups were not as fortunate to find deposits of iron ore, and so continued moving south as well. With these groups of people continually moving south, the knowledge of how to smelt iron came to the country that is now known as South Africa. Historians and geologists have found many places in our country where Iron Age settlers lived and built their smelting ovens. Studying these places has helped us to learn more about the history of these people.

The Iron Age people also knew how to make pottery by baking clay. The styles of pots and artwork found at these Iron Age sites have helped historians to determine the general date when these sites were occupied. The Iron Age people built huts and cattle kraals as well, and these ruins have been studied in places right across the country, from Mpumalanga to the Kei River.

Initially, iron-ore deposits were discovered by the Iron Age settlers as the deposits were exposed by soil erosion. Soon the settlers learnt how to find sources of iron ore by studying the different types of rock in the area and comparing it to other sites where they had found iron ore. About 1300 years ago, holes and shafts were being dug to produce the ore. A lot of trees were required near the iron-ore deposits, as the smelting process required a lot of charcoal to provide enough heat. A supply of fresh water was also important.

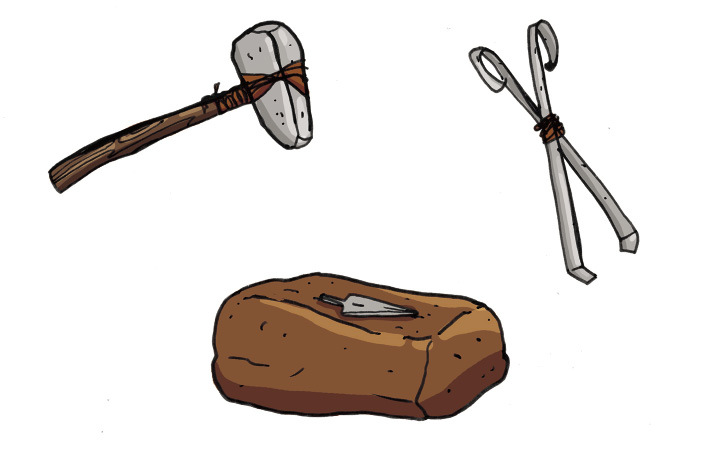

The process of smelting ore was regarded as a secret to be kept by the older men of the community. They would build a clay oven that had a small hole at the top as a chimney, and three or four other holes on the side where air could be blown in. To smelt the ore, it would be put into the oven in layers of ore and charcoal, then the charcoal would be set alight and a lid would be placed over the burning fire.

The men used "bellows" made of soft goat's or sheep's skin to continually blow air into the oven to create the high temperature needed to smelt the ore. This could take many hours, often a whole day or night. When the charcoal was finally burnt out, the oven would be opened and a lump of iron removed.

This lump would be heated over another fire and hammered into the shape of the tool or implement required. It was a difficult process, but it changed the way the people lived at that time, and so it is one of the most important eras in our history.

Notes: Iron Age technology

Topic d: the equality or inequality of job opportunities in mining for women and men

Discrimination against women has been an ongoing struggle across the globe for centuries. Women were, and in some countries are still, mostly seen as second-class citizens under the control of their fathers, husbands or other male members of their family. Women were expected to stay at home, clean and cook for the family, and raise the children, often without any help from men. Very few women received a proper education or were allowed to work for money. Those who did work, mostly did only part-time jobs and for little money. They often got married and/or had children at a young age, before they could study to qualify for higher-paying jobs.

There were many women who fought hard for the rights of all women, including the right for women to vote in elections. In many countries, women were first allowed to vote only about 80 to 100 years ago, because many men thought women were not clever enough to vote. Many of the protesting women were put in jail and even mistreated for their actions.

For us to understand gender bias, we have to understand that it develops from a very young age. Girls are often taught that they cannot do what boys can, but is this the truth? For instance, boys play with toy cars and girls play with dolls. This often leads to the mistaken ideas people have about adult men and women. Many people still think that women are more emotional than men, have to be pretty, have to be willing to have children and have to care for their families. And many people still think that only men can be physically strong, that only men are clever and hard-working enough to do jobs with a lot of responsibility, that a real man does not show his emotions and that a husband has to only contribute financially to his family.

But what is gender bias in work situations? It is when one gender is perceived to be superior to another, and this gender is given more or better employment opportunities as a result. During the twentieth century, a lot of research was done on the physical and mental abilities of men and women, and it was proven that men and women are equally capable of doing most jobs. There have been changes in laws that prohibit discrimination on the basis of gender, and as a result the number of women in the workplace has increased rapidly.

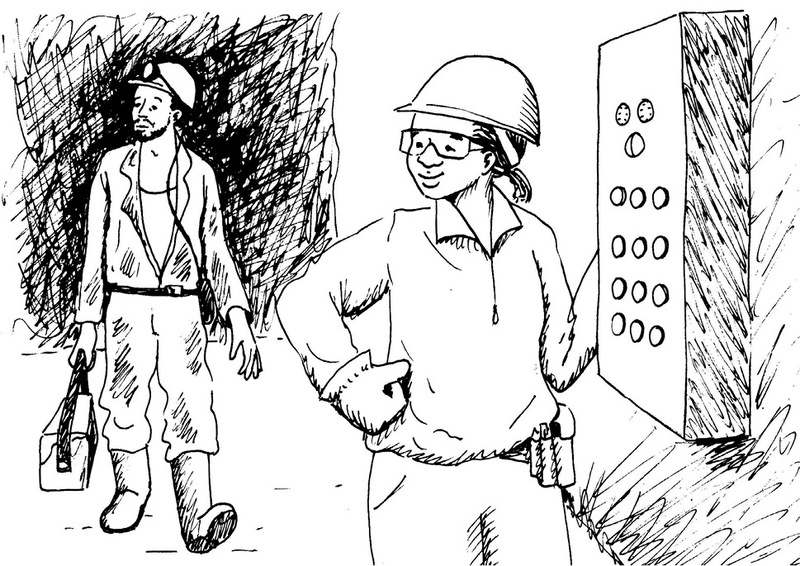

So, when you think of people working in mines deep underground, what picture comes to mind? You probably see a man, physically strong and holding a drill in a dark hot tunnel. Why do you not see a woman holding a big drill, deep in a hot dark tunnel?

Until the early 1990s, women in South Africa were prohibited from working in underground mines. As we said earlier, since 1994 there have been numerous changes to the laws in South Africa to reduce and remove gender and racial inequalities within different industries. The mining sector was one of them, but statistics show that gender equality is not happening as quickly as it should be. Even today, only 5% of mineworkers in South Africa are women, and the majority of these work in offices as clerks or administration officials. Very few women work directly with the physical extraction of minerals. There are, however, a lot of women involved in informal mining, such as extracting coal, clay, copper and other minerals for the sake of their own and their families' survival. This proves that women are physically capable of doing the job, even though they are not employed as physical workers.

These days anyone who wants to work underground can do so, but they have to pass a fitness test first. This test is not only for strength, but for stamina as well. Stamina refers to the ability to do physical work for a specific period of time without harming your body. In addition, the miners have to pass a heat-tolerance test and it has been discovered that women can handle high temperatures better than men!

A heat-tolerance test is used to make sure that people can handle long periods working in high temperatures. The temperature in an underground mine is much hotter than at the surface.

So it doesn't matter if you are a man or a woman, if you pass the test you can work underground, mining ore.

Another area where a bias has been noted is in the payment for work done. Although women are doing the same job as men, they are being paid less than their male counterparts. This practice is called wage discrimination, and there are also laws against this type of unfairness. However, because some women are desperate for work, they have no choice but to accept lower wages.

Apart from wage discrimination, there are many reasons why women are still not working in the formal mining sector to the same extent as men. For example:

- low levels of training amongst women, specifically a lack of technical training,

- unsupportive work cultures in the mining sector, despite changes in law,

- a lack of mentorship and facilities,

- the physical nature of mining, and

- historical bias against women in the mining industry.

For women to gain better access to careers in the mining industry, the perceptions that men and women have about this situation needs to change. Women have already proved that they are capable of doing the same work as their male counterparts, and therefore they should not only be allowed to do so, but they should also be rewarded and promoted by the same standards.

Notes: Gender bias in mining

Team discussions and preparation of reports

After reading through each of the articles in the previous lesson, you were asked to make notes on what you understood to be the main problems or opportunities presented by the topic. You were also asked to find out more about each topic.

You will now work in your teams to prepare a report on the topic allocated to you. This report needs to consider the history and background of the topic. The reports must be informative and, when necessary, need to be investigative. For some of the topics, the team might have suggestions as to how problems can be solved or lessened. These suggestions will form an important part of the report.

Each team will give a short presentation to the class next week. You have this whole lesson to prepare. Each of you has to do a part of the presentation.

To help you prepare your report, some additional question are given below about the four different topics. Discuss the questions about your team's topic now.

Topic a: the impact of mining on the environment: acid mine drainage

You are not required to give solutions to acid drainage: these are very complicated and expensive processes! The purpose of this exercise is to understand how acid leaking from old mines can cause problems, and how communities can take precautions to not be affected by it.

1. What is acid mine drainage?

2. Why do you think it wasn't seen as a problem when the mines were started?

3. What effect can acid mine drainage have on communities, water supplies, houses and other buildings, and on the environment?

4. How can communities affected by acid mine drainage be assisted?

5. Who should be investigating the problem, and who should be assisting with the solutions?

6. What should the mining industry be doing to fix existing problems and prevent future problems?

Topic b: the impact of mining on the environment: dust pollution

1. Give a short history of why there are so many mine dumps in South Africa.

2. Why do towns develop around mines?

3. How does dust blowing from mine dumps have a negative impact on people and the environment?

4. Why is dust from mine dumps more dangerous than dust from fields?

5. How can dust blowing from mine dumps be prevented?

6. Why is the problem in Johannesburg reducing? Give a few reasons, and then make suggestions as to how you think other communities can learn from Johannesburg's experience.

7. What other ideas does your team have to reduce the problem around the country?

8. When new mines are dug in future, what plans should be made by the engineers to avoid problems with the mine dumps they produce?

Topic c: indigenous mining in south africa before themodern era

1. Why is the history of early mining important to understand and study?

2. Why did groups of people from North Africa move southwards?

3. How important was mining as a skill to the migrating people?

4. What resources would the migrating people look for? Why were these resources important?

5. How do we know so much about the Iron Age settlers? What would you look for if you were searching for signs that they had lived at a specific place?

6. How has mining affected the growth of South Africa?

7. What does the future of mining look like?

Topic d: the equality or inequality of job opportunities in mining for women and men

1. What is gender bias?

2. Has it affected the growth of industry and commerce (business) in South Africa, and if so, how?

3. What has been done to change and get rid of gender bias in the mines of South Africa?

4. Does your team think that the changes have been successful?

5. What else can be done to reduce gender bias in mining and other areas in the workplace?

Homework: prepare to ask and answer questions

Read through all four of the articles given in lesson 5.1, so that you know the background about the other three topics that other teams will talk about. You will ask the other teams questions after they have given their presentations. Make a few notes below to help you:

Presentation of reports

During the previous lesson, each team spent the lesson preparing an oral report on one of the mining topics. You were all asked to read the articles on the other three topics to enable you to ask questions on the other teams' topics.

Get together in your team first and spend five minutes revising your presentation. You will only have two minutes to do your presentation. You can use visual aids such as a poster to show the class what you mean.

Your teacher will then ask the teams in turn to make their presentations. Remember to ask the other teams questions after they have presented their topics. The idea is not to make them look bad, but to learn from them by asking those questions.

Homework: reflect on the weeks' work

1. What was your topic about?

2. Compare advantages and disadvantages of the mining industry to South African society.

3. What can be done to improve people's understanding of mining?

4. What can be done to make mining more beneficial to society?

Next week

Next week, you will start your Mini-PAT for this term. You will design and build a model of a lifting system for a mine. You will also prepare a tender for building the lifting system.